Lightac Industry Co.,Limited

Business:Supplier of LED lighting for indoor and outdoor, commercial and residential application, etc.. OEM / ODM acceptable, this site is only for wholesale business, if you are interested in drop-shipping retail business, please go to our B2C website www.lightsb

Website: www.lightsb2b.com; E-mail: sales@lightac.com

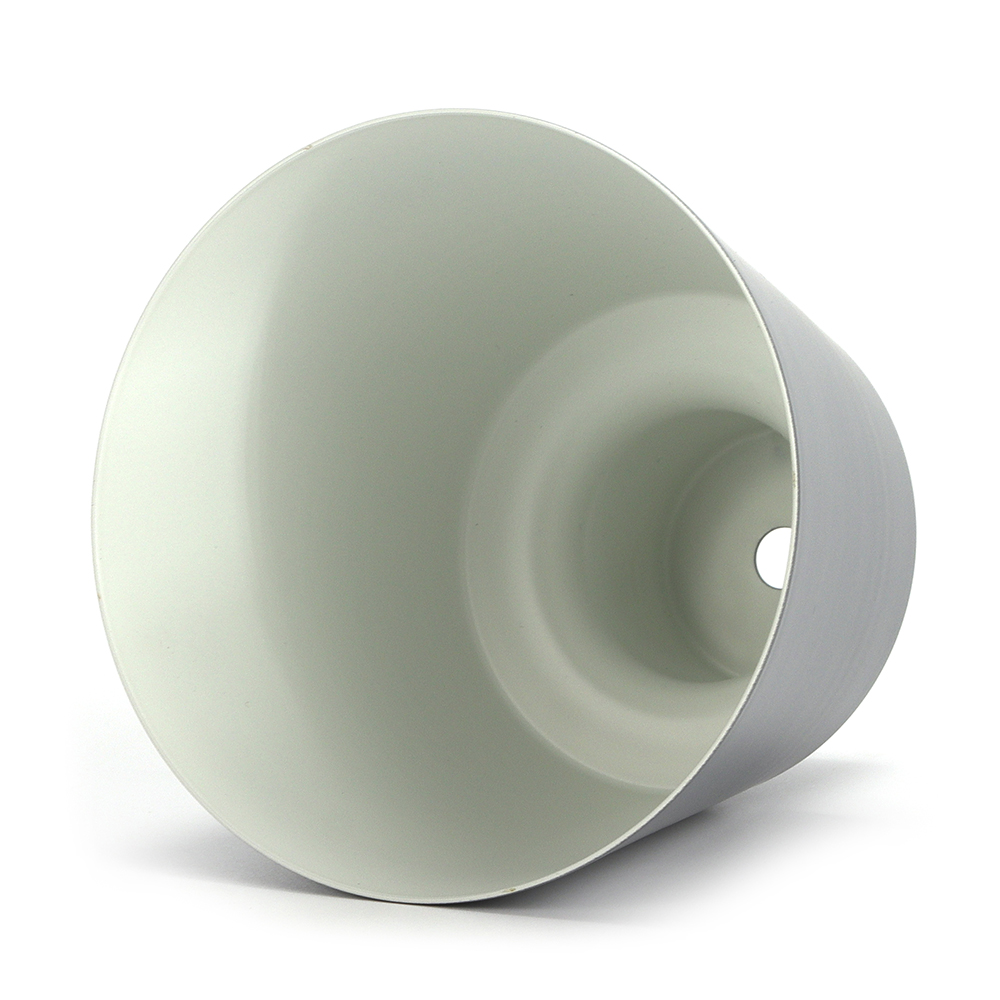

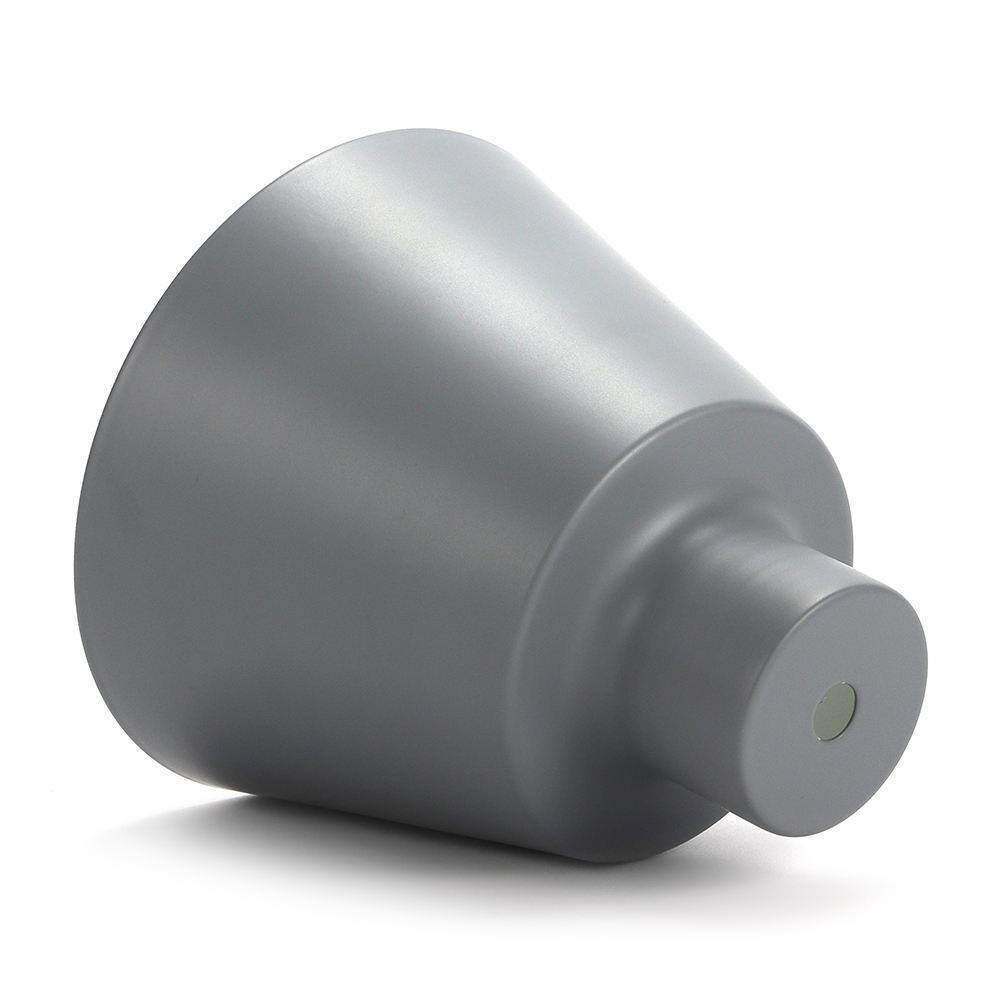

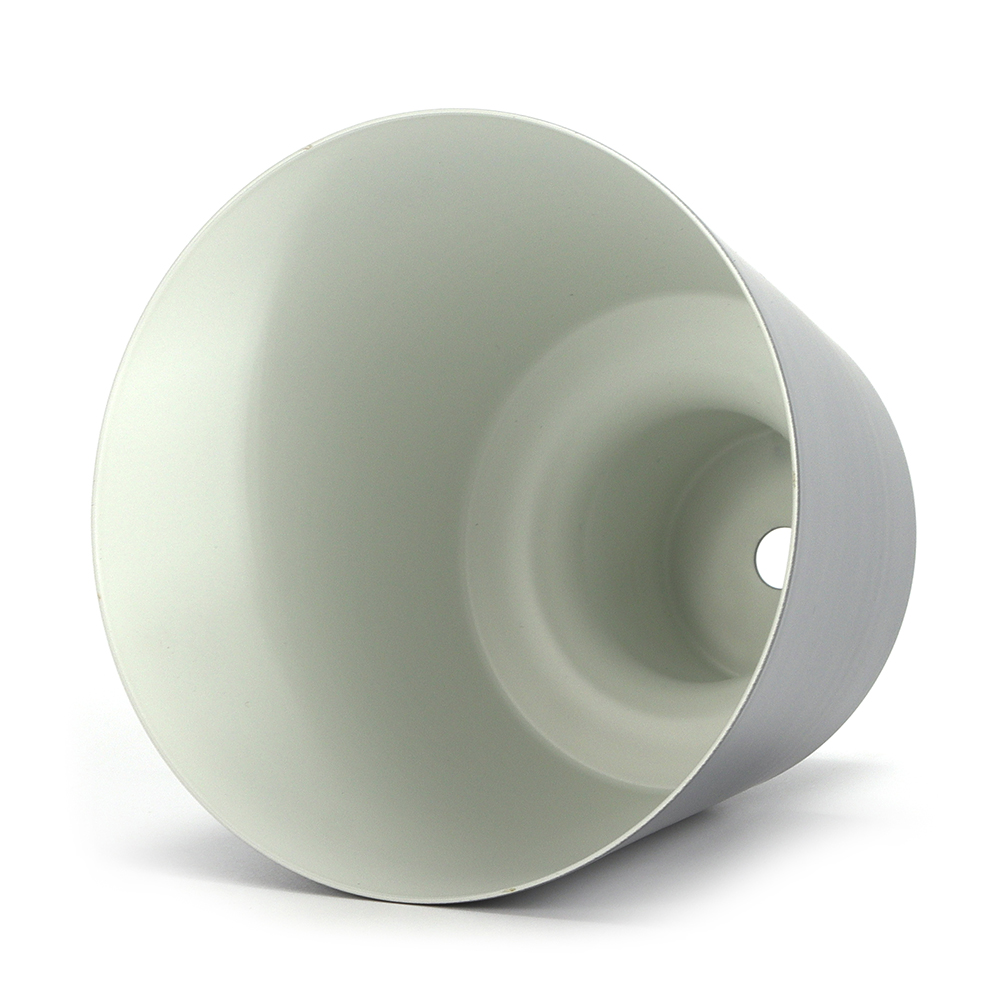

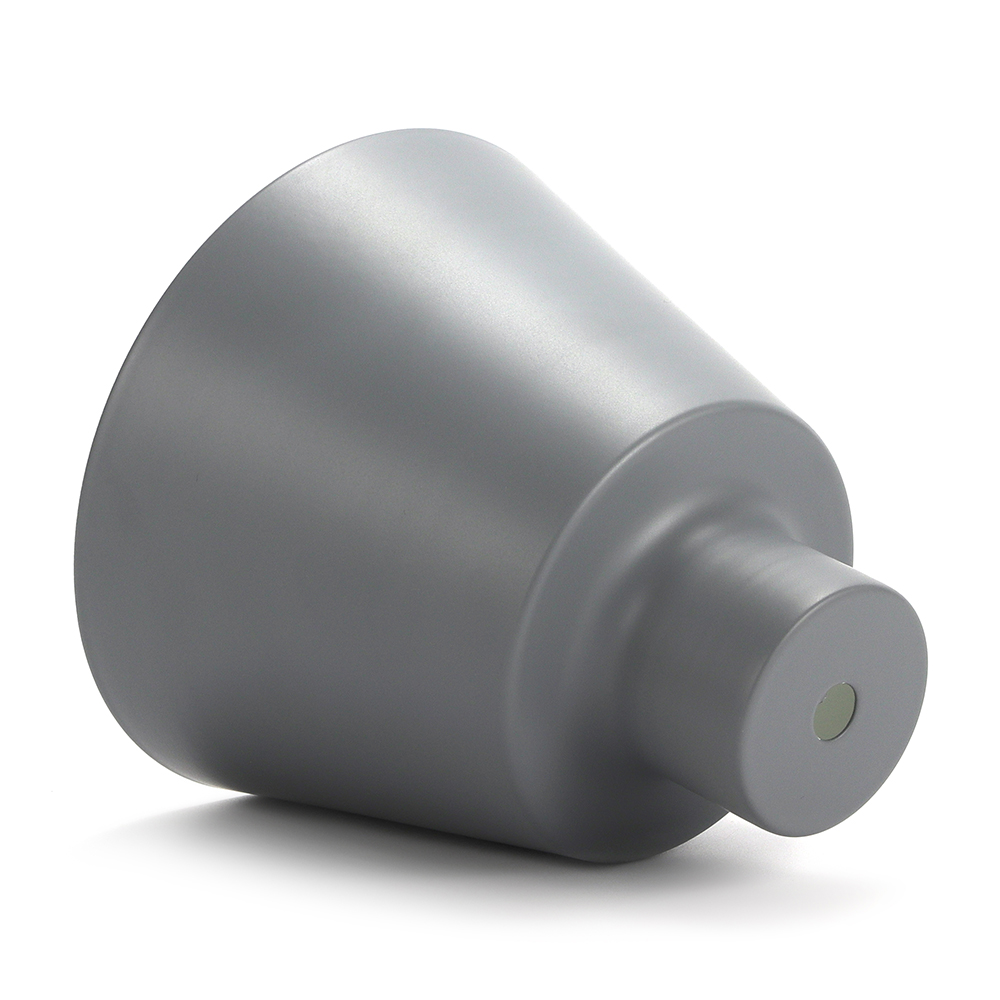

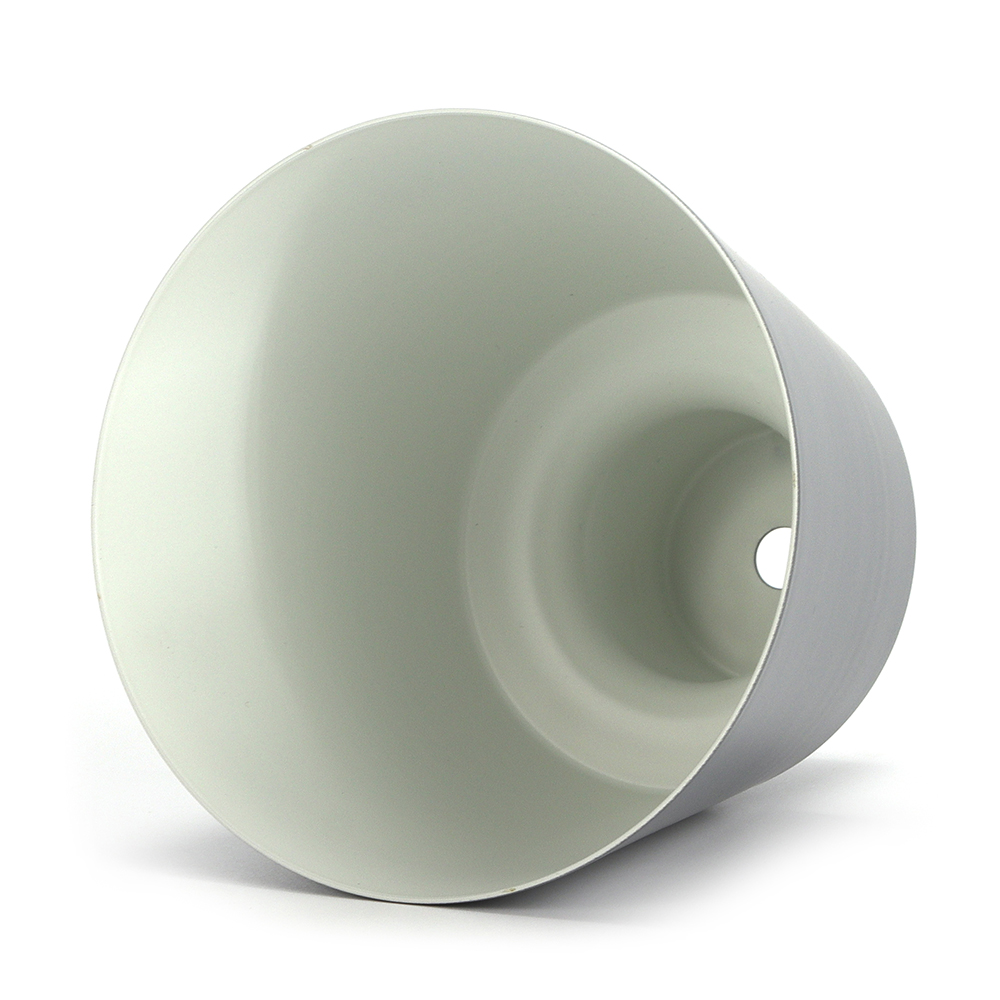

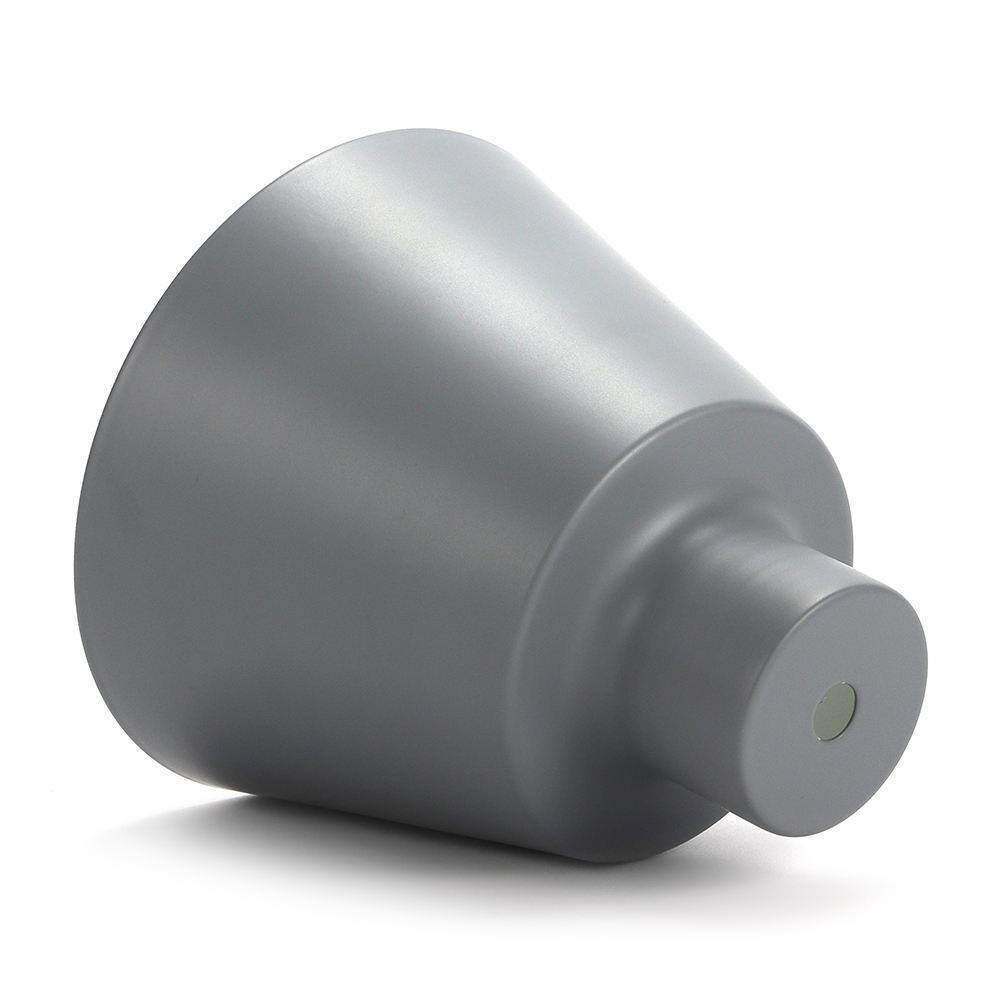

Vintage Industrial Lampshade With Lamp Holder Lamp Cover With Socket Black Iron Lampshade With Lamp Socket

Product descriptions

Spinning for lighting parts

The definition of spinning:

Spinning is to fix the flat plate or hollow blank on the mold of the spinning machine. While rotating the spindle of the Lathe,

press the blank with a rotating wheel or a rod to make local plastic deformation. Spinning is a special forming method. The spinning, flanging, shrinking, bulging and crimping processes of various shapes of the rotating body can be completed by a spinning method.

Advantage:

1) spinning equipment is simple and flexible, and has great flexibility.

2) There are some complicated shapes, while punching is difficult or impossible to complete, it may suitable for spinning.

3) High material utilization rate and low production cost. Compared with machining, it can save materials by 20%-50% and cost by 30%-70%.

4) Spinning parts have high dimensional accuracy and surface roughness is easy to guarantee. In addition, the parts with spin forming have good fatigue resistance, yield point, tensile strength and hardness are greatly improved.

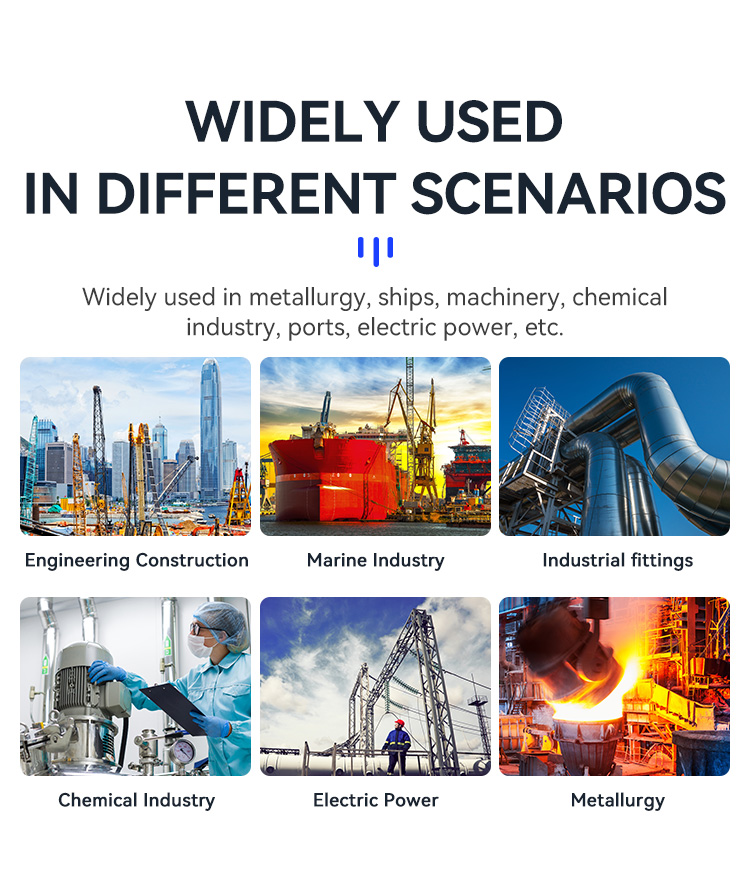

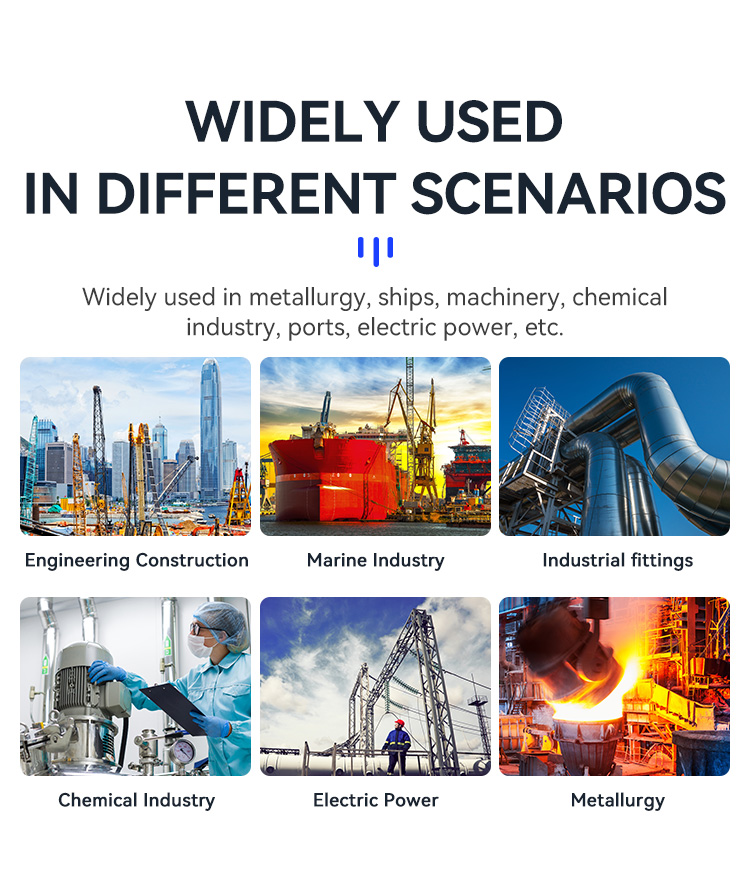

| roduct name | Light metal Spinning |

| Material | Aluminum |

| Application | Down lights, Ceiling Lights ect. |

| Dimensions | Customized Sizes |

| Surface treatment | RAW, White, Black |